MKE Iron Erectors Inc. is a female-owned business that was founded in January 2019, right before the COVID-19 pandemic, by Barbara Sheedy. The Union Ironworking company provides a range of services to its clients, including placing rebar and post-tensioning cables into concrete and erecting miscellaneous metals and miscellaneous structural steel. While the company may be early in its journey, Sheedy has a wealth of experience, having worked in the construction industry for 28 years. She started out on the mechanical contracting side before transitioning through accounting and finance before landing with a flooring contractor. Following some structural changes to that company, Sheedy decided to go it alone and MKE Iron Erectors Inc. was born. Its goal is both a simple yet essential one. “We can do everything essentially from a Starbucks canopy up to a 47th-floor skyscraper – our job is really to provide solutions to clients that save them time, money and stress.”

The company has built a large portfolio of clients and has completed work on all kinds of projects, from skyscrapers to institutions including hospitals and schools. In addition to this, it supplies services for road construction and other infrastructure projects. According to Sheedy, by being on hand to renovate existing structures, the company is never far from the next opportunity. “In the United States we have a bunch of strip malls and when one business goes out, another one comes in and they might reconfigure how that HVAC system flows in a space. So, we can go in and help them revise and renovate those areas”.

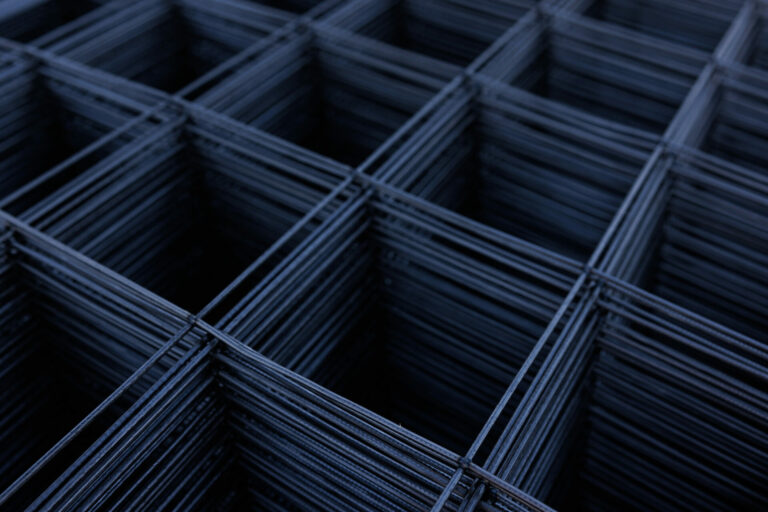

Work at the DeLonge required extensive pre-tying.

MKE Iron created custom jigs making tying and lifting safer

and more efficient.

Now celebrating its fifth anniversary, the team at MKE Iron Erectors Inc. is clearly doing something right. The key to its success, according to Sheedy, is simple – the quality of the completed projects and its union workers. “What we’ve tried to do is try to attract the best talent through the culture that we have created in the company. It is really more of a family atmosphere. We really care about the people. I’ve always been a lifelong learner and I encourage that with all of my employees too, both non-collective bargaining and collective bargaining guys. So as the construction industry and just the world in general has continued to evolve and have to get in pace with AI, with labour shortages, we actually have to kind of pivot and innovate. Our success has been basically doing what we say we’re going to do.”

This reference to keeping pace with technological advances is not just lip-service, either. MKE Iron Erectors Inc. was the first contractor in Wisconsin to bring robotics into bridge building. Being driven by the need to excel across the board is at the heart of MKE Iron Erectors. For Mark Redetzke, Director of Marketing and Business Development at the company, this goal and perspective is not something he has ever encountered before in his long career. “Personally, I think being an old man who’s worked for multiple companies I’ve never worked for an organization that stood behind its vision and values as much as MKE Iron Erectors. Our vision is to build prosperity and better communities, and we live up to that by picking projects that really move the needle for communities – we’ve altered the Milwaukee and Madison skylines significantly.”

These goals, unsurprisingly, extend to its safety measures. The company takes the OSHA safety guidelines very seriously to ensure the safety of its workers. The company has gone beyond industry guidelines, however. One stark statistic that is of great importance to the company is the fact in the US, construction is the second highest industry for suicide. In fact, construction workers are five times more likely to die by suicide than the national average. Sheedy explains how the company strives to protect its workers from the pressures that can lead to such horrendous outcomes. “We instituted that if any of our foremen need a mental health day – because the Union guys don’t get paid vacation and a lot of guys go to work when they’re not feeling well, even if it’s mentally not feeling well, because they need to put food on the table. So what I say to my guys is, I need you to be 100% for me, I need you to be in the right mind space so that you are safe on the job site and if you need to take a mental health day, no questions asked, I will pay you for your mental health those days that you want to take off.”

“Now celebrating its fifth anniversary, the team at MKE Iron Erectors Inc. is clearly doing something right.”

This standpoint is a refreshing and inspiring one in an industry that promotes growth and profit about all else. Speaking further on the company’s aim, Sheedy explained that it is only through open communication that communities can thrive. “We’re here to solve problems. Everybody has their own perspective, their own view, their own viewpoint. You need to respect that, but let’s try to figure out a problem and mutual resolution together.” This openness, however, needs to be followed through on. In order to build trust, Sheedy says, accountability needs to be guaranteed. “But I also hold people accountable – that is unheard of in today’s society. If somebody says they’re going to do something or if I say I’m going to do something, I do it and I expect the other person to do it.”

MKE Iron Erectors Inc. believes that its workforce is one of the most important elements. With superior training, the team has won two impact awards for projects it has completed. As a unionized staff, the company can reach out to other professionals around the U.S. to find someone who can come in and assist if it encounters a particularly complex or niche job. The benefit of this is that the in-house team learn and develop accordingly. “So now my guys that were working with the local guys have learned something, so the next time I bid a job like that, I might not need to borrow those guys – our guys learn something and are able to perform the work now.”

Recently the team completed The Couture building, a 47-storey high-rise multi-use building which will comprise retail space, condos, and a penthouse. Impressively, the light rail system in Milwaukee will also pass through the first floor of the retail space. As it is situated right beside the lake with four underground stories, it was a complex job involving both rebar and post-tensioning. Redetzke said: “The Couture is definitely one of the crown jewels of Milwaukee, and I don’t think you can overestimate the impact that we’ve had on the area. We’ve helped work on the newly remodelled Wisconsin Centre, which is a huge Convention Centre that’s going to host the Republican National Convention this year. We’ve helped stabilize Milwaukee City Hall by reinforcing its base – it’s a 50,000-ton structure that was starting to sink. I think it is incredible how we have affected Milwaukee in such a deep way through out projects.” Speaking about its workforce, he added: “That’s where our ironworkers amaze me – their ability and resilience in how they can approach and find solutions for things that just come out of left field. They really know how to step up and solve the situation.”