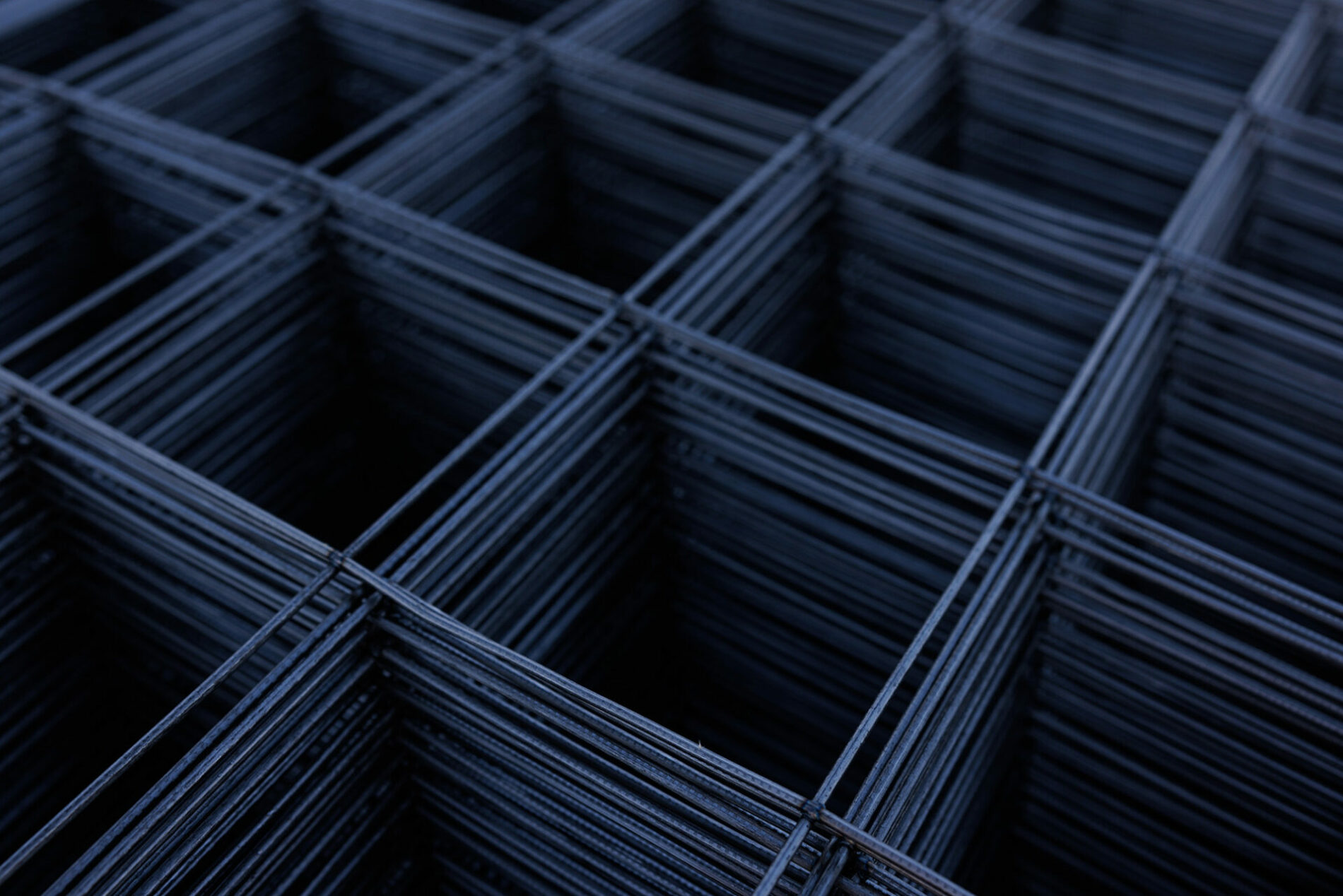

Laurel Steel produces the tough stuff, but it’s the company’s people who provide the foundation for its nearly 60-years of booming business. To last so long in business, it is vital to have a foundation built on innovation, excellence and have a knack for cultivating ongoing relationships with clients. Unsurprisingly, Laurel Steel possess the lot. If you’re looking for a high-quality, low-cost steel producer, Laurel Steel has likely come up in your research. Quickly, they have become the industry’s North American go-to, offering a full range of shapes, sizes and grades for today’s most demanding applications. From cold finished bar, to wire products and welded wire reinforcing mesh, Laurel Steel offers customers access to the most comprehensive steel solutions.

Established in 1967, Laurel Steel has emerged as North America’s premier supplier of cold-finish bar, cold-drawn wire, and welded wire reinforcing mesh. With a rich history spanning decades, the company has continuously refined its safety and quality standards, constantly exceeding industry requirements and prioritizing customer satisfaction.

Located in a state-of-the-art, 350,000-square-foot facility in Burlington, Ontario, Laurel Steel is a wholly-owned subsidiary of Nucor Corporation – North America’s most diversified producer of steel and steel products. As a proud member of Nucor’s Family of Brands, Laurel Steel is part of a legacy committed to delivering the highest value products, services, experiences, and relationships to ensure long-term success for its customers.

Laurel Steel customers are kept involved to ensure that product development remains on track and ultimately achieves the client’s pre-defined objectives. From the moment an order is placed, Laurel Steel ensures quality at every step via a customer-specific inventory program. Its products are manufactured to both industry and customer specific specifications and packaged to meet client needs.

Laurel Steel boasts an automated, high-density system for storage of cold finished bar, as well as a humidity-controlled storage system for drawn wire coils. All this done to ensure the highest level of surface quality and integrity of the products while offering sufficient storage levels of various product sizes to handle both small and large orders with little to no lead-time (J.I.T.).

Laurel Steel’s commitment to quality is far reaching. Certified to ISO 9001, ISO14001, TS16949, amongst other standards. Laurel also offers extensive metallurgical capabilities and services providing the high level of quality assurance possible. These services include online testing, offline testing, state-of-the-art lab equipment, failure analysis and on-site metallurgical testing. Laurel Steel is effectively a one-stop shop for steel products and QA, ensuring quality product, every step of the way.

For the company, this quality always goes hand in hand with safety. By ensuring the highest standards of safety are retained, Laurel Steel produces products that excel right across the board. As JD Russo explains, ensuring staff and customers are in good hands is a vital aspect of the business. “Safety is a core value for Nucor, and there is nothing more important to us than the well-being of our teammates. We are coming off of our third straight safest year and will continue to set safety records in the future.”

“Laurel Steel is part of a legacy committed to delivering the highest value products, services, experiences, and relationships to ensure long-term success for its customers.”

Laurel Steel’s team of leaders attribute its success to its Nucor affiliation, providing its subsidiary with a broad range of products and solutions, further positioning Laurel Steel as a vital component in the construction ecosystem. As Will Klages mentions, “Our ideal customers want to grow into the future, not remain stuck in the rigidity of the past.” This is particularly true as it relates to environmental and sustainability goals. Laurel Steel is committed to adopting a more sustainability-focused business model, paving the way for a roster of like-minded clients who share the same values. “Sustainability is definitely a focus; we are committed to reducing our carbon footprint. Our Electric Arc Furnace (EAF) supplied steel, consumes and recycles scrap steel in a process that greatly reduces greenhouse emissions. Steel can be infinitely recycled without quality loss. Our steel products are made with over 96% recycled content.” Last year alone, Nucor turned 20 million tons of scrap into new steel products and in addition to these measures, the company is currently exploring the feasibility of capturing and storing its GHG emissions.

Today, the main challenges Laurel Steel faces can be attributed to an accelerated demand for construction, thanks to exponential population growth and the subsequent infrastructure needs that come along with that. The team overcomes these challenges by aligning with the changing construction landscape and actively addressing issues like labor shortages and sustainability concerns, ensuring it remains well-equipped to succeed on its mission to deliver the greatest value for its clients. This includes constant, strategic recruitment to staff up its teams.

Reflecting on Laurel Steel’s early days, Josh Renneboog acknowledges the company’s roots in supporting Harris Steel, which ultimately spurred the rapid growth the company continues to see today. The move to Burlington in 1972 marked a pivotal moment, and cold-finish operations became the primary focus. For Laurel Steel, the only other constant (besides consistent, warp-speed growth) is change. “In the next three years, we’re looking to experience continual growth in not only the construction and mining industries but in the engineered structural mesh markets,” says J.D. Russo.

BrandonBurkPhotography.com

BrandonBurkPhotography.com

BrandonBurkPhotography.com

Laurel Steel continues to future-proof its business model and in 2023, the company even commissioned a new engineered structural mesh welder, capable of service infrastructure commercial/industrial, and residential construction sectors. This has expanded the company’s capabilities to enter new markets and provide innovative solutions. This initiative reflects the company’s commitment to staying at the forefront of industry advancements.

Education and ongoing initiatives for the next generation underscore Laurel Steel’s dedication to sharing knowledge. Lunch and learn sessions, webinars, and collaboration with trade associations demonstrate a commitment to education architects, engineers, and other industry professionals. “We spend a lot of time trying to get in front of people to talk and educate, not even trying to get a sale, just trying to educate people on the different construction methods,” says Will Klages.

As Laurel Steel envisions the next three years, the focus remains on continual growth and support for the construction and mining sectors. With an eye on expanding further into the engineered structural mesh market, the company remains agile in responding to industry trends and challenges. Laurel Steel’s journey from its inception in 1967 to its current position as a leading supplier in the construction industry reflects a commitment to excellence, innovation, and customer satisfaction. Anchored by Nucor’s strength and guided by a dedicated team, Laurel Steel is poised to continue shaping the future of construction solutions in North America and beyond.

The secret behind nearly six decades in business? The answer, for Josh Renneboog, is simple. “Our company’s success is very easily defined by our success our people, our team. There’s no question about it, the group of people that work here at Laurel and Nucor make all the difference. It’s why our company, our corporation is successful.”

J.D. Russo adds, “We live each day with gratitude for the families, customers, staff and partners that make our work possible.”

If you are in need of a new supplier of cold-finish bar, drawn wire, and/or weld wire reinforcing mesh products and would like to connect with a Laurel Steel team member to see how they can support your upcoming projects, please visit the Laurel Steel website, or email them at [email protected]