Simply put, when it comes to steel, Techno-Weld works on anything cold to the touch. Family owned and operated since 1985, the company is a leader of structural steel and miscellaneous metals, specializing in detailing, fabrication, and installation of structural and miscellaneous steel for residential, commercial and industrial projects. Everything is done in-house at its premises in Mississauga, Ontario —the seventh largest city in Canada. The company services a wide range of local and national clientele, handling any and all structural steel and miscellaneous metal needs. Techno-Weld one of the largest fabricators and suppliers of structural steel and miscellaneous metal in the province of Ontario. The team’s certified Canadian Welding Bureau welders and steel fabricators prepare a wide range of structural steel shapes, frames and products.

But all this didn’t happen overnight. The team has spent nearly four decades honing its customer service approach and processes. With a focus on quality and by offering tons of value-adds to clients like design support to help guide project plans from the outset, ultimately the client saves both time and money. Despite its success and breadth of service offerings, however, Techno-Weld wasn’t always the household name it is today.

“When my dad and the founder, Zeki, came here from Turkey in 2000, finances were tough,” says Mike Gurlek, Project Manager. Having brought the company to Canada from overseas, Zeki found a very different landscape. Effectively, the family were forced to start over, building Techno-Weld from the ground up, again. “There was no shop, it was just a small garage with one truck.”

Financing material and equipment to grow the company was the biggest hurdle, but over time volumes increased. This early success ensured that the demand for services outpaced any incurring costs to run the company. Thirty-eight years later, the biggest challenge the company faces is keeping up with demand. Much of this, Mike says, is down to the quality services that clients have come to know and trust from Techno-Weld. “We don’t skip any of our quality control methods, even though these steps have in the past delayed projects,” says Mike. To combat delays and streamline processes, the company has implemented some new strategies and processes, they now operate the fabrication plant 24 hours a day 7 days a week and have 3 shifts of employees, which allows the team to get steel out the door faster without sacrificing quality. Today Techno-Weld services clients across Ontario and into Quebec, working with larger construction and engineering firms on large-scale projects – anything from airports to universities, community centres and hotels.

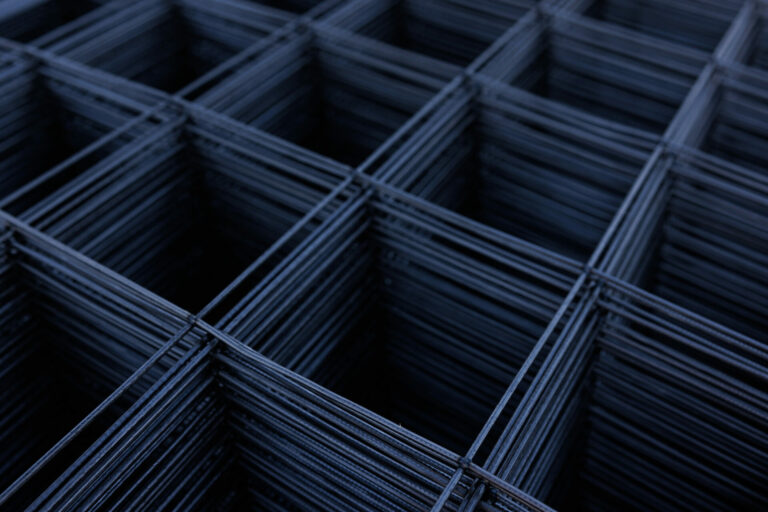

Working from solid plans, the team at Techno-Weld converts raw steel into cut, drilled, welded, modified, and painted – ready to deliver. Not only does Techno-Weld deal with structural steel, it also specializes in steel stairs, steel railings, hand railings, metal deck, steel gates, steel fences, rooftop units (RTU) frames and all types of welding and renovation/restoration projects.

“Techno-Weld boasts a team of over 40 experts in design builds and fabrication.”

Techno-Weld boasts a team of over 40 experts in design builds and fabrication, well-versed in what it takes to facilitate a steel erection process. In addition, the fabrication services include miscellaneous steel products to reflect special project needs ranging from steel joists to metal decks, handrails, mezzanines, commercial warehouses and more.

With years of experience in miscellaneous and specialized structural steel projects engineered to detail, the company proudly installs:

• Steel stairs

• Steel railings

• Steel framings

• Metal deck

• Steel gates

• Steel fences

In addition to providing the materials and fabricating, Techno-Weld also provides professional installation services to get the job done right, on time and under budget. Projects include:

• High-rise Buildings

• Warehouses & Hangars

• Stairs & Spiral Staircases

• Canopies

An example of Techno-Weld’s commitment to quality workmanship is exemplified through their recent long-term care facility project, 128 L.T.C Facility in Napanee, ON. The LTC facility houses 128 rooms and Techno-Weld has been involved in all aspects, handling the structural steel work as well as the miscellaneous steel aspects.

They are also in the process of building a mega school in Parry Sound, ON in partnership with Vanhorne Construction. When complete, the school will house 5,000 students from junior kindergarten all the way up to senior high school. The Techno-Weld team is responsible for erecting the structural steel, steel joists, roof deck, miscellaneous metals and also providing design support to ensure a smooth project delivery process.

Techno-Weld also recently did work for Hamiton’s McMaster University campus. The team renovated and erected the steel for a cooling tower and are currently in the process of phase two of this project. Phase 1 steel was complete in partnership with G.S. Wark Construction and Phase 2 with Ira McDonald Construction. This project involved hoisting steel up 80 feet in the air with the support of a 200 ton crane. Given that these projects take place in locations densely populated with students and pedestrians, safety is of utmost importance.

No matter the size and scale, safety on the worksite is always Techno-Weld’s utmost priority. When it comes to safety in the workplace, Techno-Weld Limited spares no expense. All Techno-Weld employees go through safety training before starting their role at the company. To ensure the highest level of safety at each work location, the company also provides site specific safety plans and daily reports. The goal always remains the same: complete projects that prioritize health, safety, and a satisfied customer.

As Techno-Weld and its team looks ahead to the future, growth continues to be the driving force behind the company. Plans are currently taking shape to move operations into a larger facility which will allow for additional investment in new machinery. The goal of this venture is to increase productivity by acquiring additional features such as state-of-the-art laser machines, beamlines, and robotic welders. This will allow the team to begin automating some of its fabrication processes to ensure the quickest turnaround times for clients.

“Our clients are generally repeat customers who have worked with us for many years. New customers always return for other projects they have. When it comes to working with us, people are really in it for the long-run, and I think that’s because we maintain our relationships, provide the appropriate workmanship and always remain highly budget conscious.”

If you are in the Ontario or Quebec region of Canada and looking for supply, fabrication, installation and/or welding of structural and miscellaneous steel for you upcoming project, submit a quote online at technoweld.ca.