Since its founding in 1965, Corbec has led Canada’s galvanizing industry through an unwavering dedication to quality, innovation, and environmental responsibility. From pioneering advanced technologies to implementing rigorous sustainability practices, Corbec stands as a leader in galvanizing and a model for other firms aspiring to meet Canada’s ambitious environmental goals. This forward-thinking approach is particularly significant as the construction sector faces mounting pressure to align with the Canadian government’s commitment to net-zero emissions by 2050.

With over five decades of expertise, Corbec’s work reflects its dual dedication: protecting steel and protecting the planet. Through initiatives like advanced emission management systems, plant-specific Environmental Product Declarations (EPDs), and industry-first educational outreach, Corbec has redefined the standards of sustainable manufacturing in steel protection.

Corbec’s commitment to technological advancement is reflected in its state-of-the-art galvanizing plants, which are among the most technologically advanced in North America. The company was the first in Canada to implement a “capture and treat” system that effectively manages process air emissions, setting a new industry benchmark in environmental stewardship. This system captures emissions at the source, minimizing environmental impact and going beyond traditional regulatory compliance.

In addition to this, Corbec has adopted comprehensive waste recycling systems that not only reduce ecological impact but also enhance efficiency. By recycling waste, Corbec minimizes resource use and positions itself as an industry leader in sustainable manufacturing practices.

The company’s forward-thinking attitude is exemplified in its investments in technologies that emphasize both environmental and economic responsibility. According to Corbec’s Executive VP of Engineering, Sustainability, and Market Development, Dr. Hellen Christodoulou, “Our commitment to innovation and sustainable practices ensures that Corbec will continue to be an innovator in steel protection, leading the way toward a greener, more sustainable future for all.”

As climate concerns intensify, the construction industry is under increasing pressure to adopt sustainable practices, given its considerable impact on the environment. Canada has set ambitious targets to achieve net-zero greenhouse gas (GHG) emissions by 2050, a goal that demands proactive industry engagement.

Corbec’s initiatives to control emissions and recycle waste place it at the forefront of this movement. By voluntarily adopting sustainable practices that align with future regulatory standards, Corbec is showing the construction industry that change is not only feasible but beneficial. This proactive stance showcases Corbec’s commitment to Canada’s sustainability objectives, underscoring the company’s role as a leader in environmentally responsible construction.

Corbec’s dedication to environmental responsibility extends beyond its manufacturing processes. The company actively supports the design community by providing resources and education to architects and designers, who play a crucial role in determining a project’s environmental impact. Through these initiatives, Corbec ensures that design professionals are well-informed about the sustainability benefits of galvanized steel and the environmental advantages of using materials that align with high sustainability standards.

Corbec’s educational outreach programs reflect a broader vision: to create a construction ecosystem where sustainable choices become standard practice. By supporting architects and designers with knowledge and resources, Corbec empowers them to make environmentally sound choices. As Dr. Christodoulou stated, “By fostering a culture of sustainability and supporting the design community, Corbec is not only protecting steel by ‘Galvanizing Better’—our brand promise—but also protecting the environment, setting a benchmark for sustainability that others in the industry can aspire to.”

“By fostering a culture of sustainability and supporting the design community, Corbec is protecting steel by ‘Galvanizing Better’—our brand promise.”

In a groundbreaking move, Corbec became the first coating supplier in North America to introduce plant-specific Environmental Product Declarations (EPDs) for its products, verified by third-party auditors and certified by the Canadian Standards Association (CSA). EPDs provide critical insights into a product’s environmental footprint across its lifecycle—from raw material extraction to end-of-life disposal. This transparency allows clients to make informed decisions based on the true environmental cost of the materials they choose.

Corbec’s plant-specific EPDs for galvanized steel products represent a significant advancement in promoting sustainability in construction. These EPDs differ from industry-wide or generic EPDs, as they offer precise, facility-specific data. This level of detail empowers clients to assess the sustainability of their materials accurately and make more environmentally conscious choices. “Plant-specific EPDs offer a new level of transparency,” explained Dr. Christodoulou. “They allow us to continually evaluate and improve our processes, and they provide our clients with confidence in the sustainability of our products.”

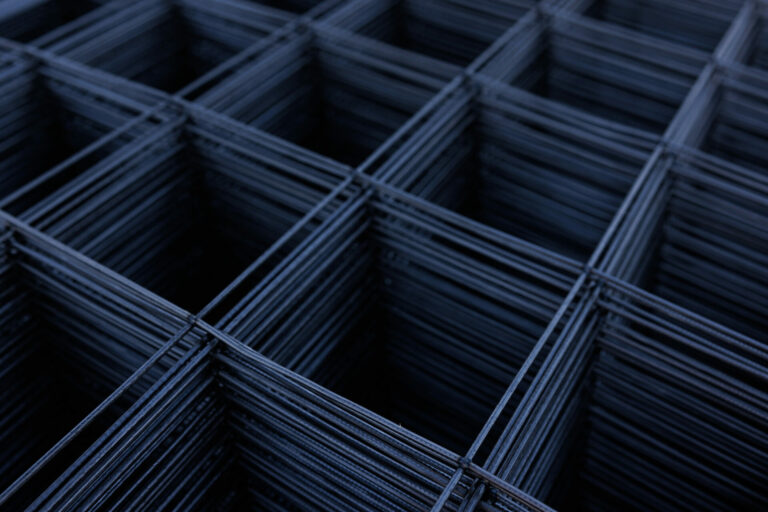

Corbec’s EPDs represent a series of firsts in North America. It is the first Canadian company to release EPDs specifically for galvanized steel products and galvanized rebar—a key material in infrastructure projects such as reinforced concrete structures, bridge decks, and roads. These EPDs allow for direct comparisons between the environmental impact of galvanized steel and other materials, highlighting the sustainability benefits of using galvanized steel in construction.

For example, Corbec’s EPDs demonstrate that its galvanized rebar has a lower global warming potential (GWP) than stainless steel rebar, which requires more alloying elements, increasing GHG emissions during production. Corbec’s hollow structural steel (HSS) sections and steel plates, according to its EPDs, have a 15% lower GWP on average compared to industry averages published by the American Galvanizers Association (AGA). This positions Corbec as a sustainability leader, demonstrating that optimized manufacturing can lead to tangible environmental benefits.

As Canada moves toward a greener future, galvanized steel products play a crucial role in sustainable construction, particularly in meeting standards set by certification bodies like LEED and BREEAM. Corbec’s galvanized products, with their long lifespan and low maintenance needs, contribute to the creation of resilient infrastructure that minimizes environmental impact. This is especially relevant for major infrastructure projects, where using durable, corrosion-resistant materials can reduce long-term repair needs and lower emissions over a structure’s lifecycle.

By championing the use of galvanized steel, Corbec is actively supporting Canada’s efforts to promote sustainable construction methods that align with national green building standards. Corbec’s dedication to plant-specific EPDs signals a significant shift in the industry’s approach to transparency and accountability. Unlike generic EPDs, which provide broad industry data, plant-specific EPDs deliver precise insights into the environmental impact of a particular facility’s output. This approach enables companies to pinpoint areas for improvement and provides clients with detailed information about the sustainability of their materials.

In Corbec’s case, these EPDs serve as a tool for continual environmental evaluation, enabling the company to refine its processes and reduce its ecological footprint. The detailed environmental data these EPDs provide also allow Corbec’s clients to make greener choices, reinforcing the role of transparency in sustainable manufacturing.

Corbec’s commitment to sustainability is more than a corporate responsibility—it is a core value that informs every aspect of its operations. By investing in cutting-edge technologies, developing plant-specific EPDs, and supporting the design community, Corbec is actively shaping the future of sustainable construction. The company’s dedication to transparency and environmental stewardship serves as a model for others in the galvanizing industry, demonstrating that profitability and sustainability can indeed coexist.

As climate change and environmental degradation pose increasing challenges for the construction sector, Corbec’s example is a powerful reminder that industry leaders can drive positive change. Dr. Christodoulou summarized the company’s philosophy: “Our commitment to sustainable practices ensures that Corbec will continue to lead in steel protection, demonstrating that environmental responsibility and innovative excellence can go hand in hand.”

As the construction sector navigates its role in addressing climate change, Corbec stands as a beacon of progress. Its leadership proves that a commitment to quality and environmental responsibility can create a more sustainable industry for future generations. Through its dedication to “Galvanizing Better,” Corbec continues to protect not only steel but also the future of the planet, inspiring others in the industry to pursue similar paths toward sustainability.