At the heart of any progress that the construction industry has made, there is one thing that has made it all possible. While skill and techniques are vital components to a developing and innovative sector, they would be nothing if it weren’t for the materials being used to create, to build and to construct. With every advancement in material and its usage, there follows a series of innovative methods, each one adapting these materials and applying them in novel ways to the betterment of the construction world. This relationship has been mutually beneficial and has pushed our global communities forward in unimaginable ways.

As building materials become ever more expensive, the construction industry now finds itself in a difficult place. Costs are rising across the board and sustainability issues are stacking up. For those at Plantd Materials, the alternative building material start-up that was founded by Josh Dorfman, along with Huade Tan and Nathan Silvernail, both former SpaceX engineers who have worked for years, designing, and building key systems and components of the Dragon cargo and crew spacecraft, we have reached a crossroads where difficult decisions need to now be made. “Throughout history, civilizations have advanced at the speed of material innovation. Timber, steel, and concrete enabled remarkable progress, but today they are the problem, not the solution. Continuing to build with these materials accelerates climate change and promises to impede progress by threatening our future on this planet.”

The solution is clear, yet incredibly complex. While innovative minds are attempting to pivot away from concrete to a more environmental and sustainably produced material, traditional values still hold firm. Additionally, alternatives remain costly and niche when compared to the historical might of concrete. However, one material is proving to be a viable source. Having been used in structure building in some capacity for many years, forward thinking individuals and companies are looking towards timber as a means of finding a sort of balance. With this in mind, it is little surprise to learn that structures built solely of wood are enjoying something of a resurgence. Techniques and practices have now advanced to the point where timber is offering genuine alternatives to brick and cement. At Plantd, the goal is to offer climate-positive alternatives to legacy building materials, while maintaining the high standards that are necessary in the construction world. “Building with Plantd materials enables home builders to offer their customers homes that are affordable, durable, and sustainable. And by sequestering atmospheric carbon dioxide within structural frames, homes built with Plantd materials will play a key role in solving climate change.”

There is one small sticking point, however, and that is time. Forests, while sustainable by their very nature, do not spring up overnight. So, what can be done to offset the lead-in times of these materials. This particular issue has been a concern for Dorfman and his colleagues at Plantd Materials for some time. In fact, he says that speed has always been an intrinsic part of what the company is trying to achieve. “We started with the question, “What’s the fastest way to remove carbon from the atmosphere and turn it into useful, durable products?” The answer to this particular challenge is already here. The company’s flagship product is a wood-panel materials designed for homebuilding. However, this material differs from the norm slightly. Incredibly, Plantd’s product comes from a fast-growing species of grass. Plantd’s proprietary low carbon-emissions production technology transforms fast-growing perennial grass into durable, carbon-negative building materials that, rather impressively, outperform competitive products on key attributes, including strength and moisture resistance. According to Dorfman, the product is right up there with anything else in the industry, too. “We see the greatest opportunity to lock away the most carbon when we make a superior product than what exists today.”

“Starting with structural panel products for walls and roofs, Plantd will fabricate building materials that are a direct substitute for traditional home construction products and require no alternative installation techniques.”

The process itself is fast-paced and highly innovative. Its plan is to replicate existing materials and techniques, supporting the industry in necessary changes without causing stress and apprehension in a fragile, post-COVID setting. In a press release announcing that it had secured $10M in Series A Funding, Plantd explained both the process and long-term strategy for its success. “Starting with structural panel products for walls and roofs, Plantd will fabricate building materials that are a direct substitute for traditional home construction products and require no alternative installation techniques. By cultivating fast-growing perennial grass instead of cutting down trees and pioneering novel production technology to minimize carbon emissions, Plantd Structural Panels™ retain 80% of the atmospheric carbon dioxide captured in the field, which is then locked away inside the walls and roofs of new homes.” For Dorfman, it goes even further. He sees the opportunity for Plantd to surpass existing materials by being a superior material, while also being more sustainable and competitive. “We can’t move quickly enough to solve climate change unless we develop profitable methods to take carbon dioxide out of the atmosphere,” said Dorfman. “We’re going to change an industry by offering builders a better product at the same price and, in the process, scale a business that can help save the planet.”

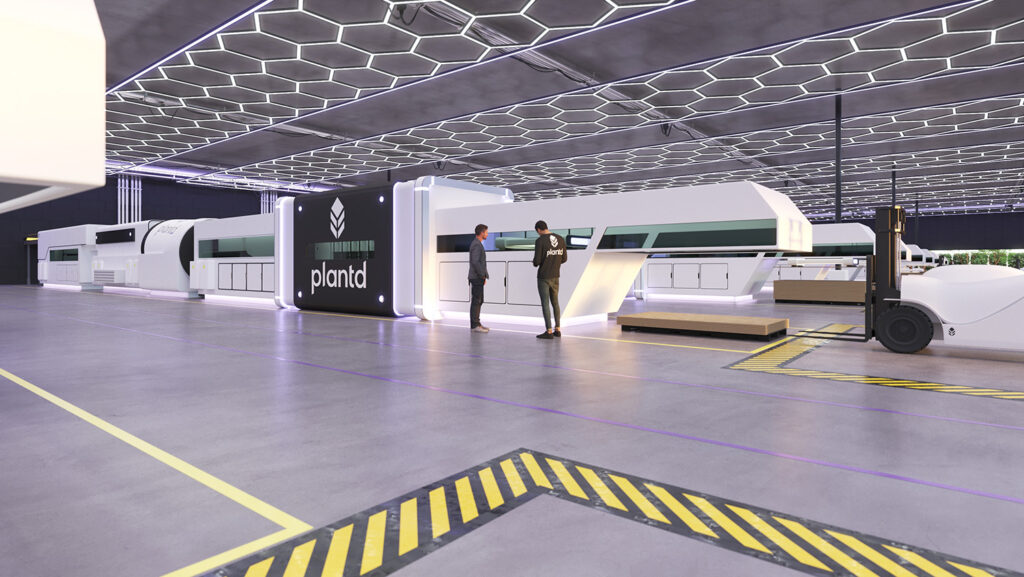

Unsurprisingly, for a company that values speed, the company has set to work, moving forward at a rapid pace. With funding secured, Plantd moved to locate and open a facility that can bring its products to the mass market. With a ribbon cutting event taking place in early May to celebrate the opening of its production facility and headquarters in Oxford, North Carolina, the company is going full steam ahead. The 80,000-square-foot warehouse and offices were originally occupied by the Santa Fe Natural Tobacco Company. An anchor facility for the town of Oxford, the location provided local jobs and farming contracts to this historic hub for manufacturing and agriculture that had previously been lost when the tobacco factory closed.

So, when faced with a multifaceted challenge that was both complex and urgent, it seems as though Plantd may have made a breakthrough. With timber becoming an ever increasingly viable, and preferrable building material, Dorfman, Tan and Silvernail have utilized the power of grass, its rapid growth cycles, and scientific innovation to produce a product that meets all requirements, and then some. Not happy with merely providing alternative, Dorfman believes the company and its product can make long-lasting change that not only benefits the construction industry, but the world itself. “Plantd is innovating across the entire value chain for building materials, cultivating new sources of biomass that allow trees to remain in the ground and pioneering new machines and production technologies that remove cost and carbon emissions at every stage of business operations. In Oxford, we see an unparalleled opportunity to reshape the construction industry, build a credible climate change solution, and bridge this rural region into the 21st-century economy. Integrating into the economic and social fabric of this area is the foundation we will build upon to drive positive impact at the local, national, and global levels.”