The construction industry takes many forms. From infrastructure and residential, commercial to environmental, there is tremendous scope across the industry for all comers. One sector of the industry that can occasionally be overlooked is that of theme and attraction building. While to some it may seem rather niche, the simple reality is that success in the sector is built on the exact same set of skills and principles as any other — hard work, innovation and professionalism. COST Inc. is a construction company based in Wisconsin, and with offices in a number of locations across the U.S. and Canada. It offers full range construction services including preconstruction, modeling and fabrication. What makes this company slightly different, however, is that it focusses primarily on Theme and Specialty Construction Services. With almost seventy years of experience in the field, it is safe to say that COST Inc. knows what it is doing.

COST Inc. started out back in 1957. John Stanwyck’s construction company was tasked to revolutionize the habitats at the Milwaukee County Zoo. With steel and iron cages no longer a welcome sight in the industry, Stanwyck started work on remodeling the zoo in a manner that was both functional are aesthetically pleasing. Since that successful initiation to the sector, the company has developed and grown immensely. Operating out of its 144,000 sq ft plant, the company has completed work in locations as diverse as theme parks, casinos, resorts, botanical gardens, residential communities, golf course, family entertainment centers, retail stores and restaurants. However, it is this integration of technology in design through construction that has led it to the highest points of the industry with no sign of slowing down. According to Tim Zimmerman, Project Manager at COST Inc., this means that the company uses a hybrid approach, incorporating cutting edge machinery with traditional methods to share its vision with a potential client. “We rely heavily on clay handmade models, which is very old school. One of the biggest components of a job in terms of moving it forward is getting approval of the model. Once the client sees the model, the job really comes to life. We use a lot of new technology such as software, but we also use an old school component in the clay model. I think it’s a huge part of our business, clarifying everybody’s expectations.

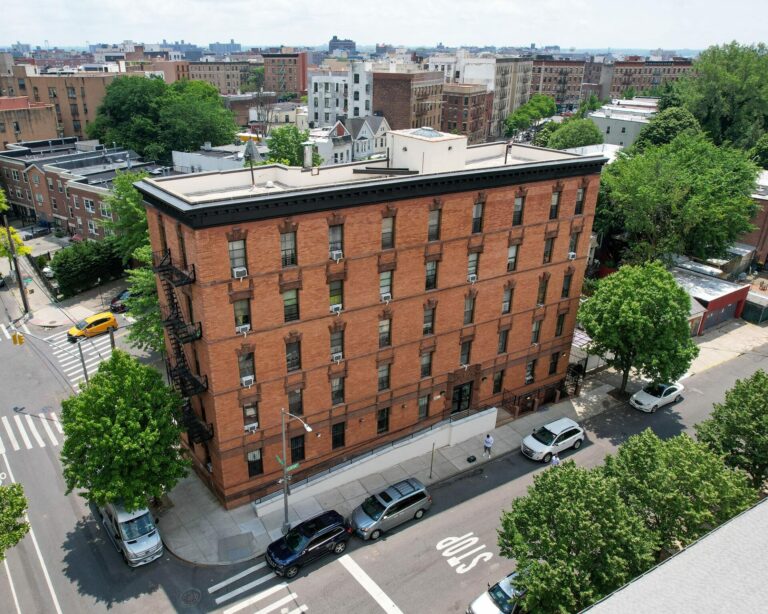

Kingdoms of Asia at Fresno Zoo – Fresno, California

This marriage between traditional methods and new techniques is echoed by Sergio Castro, Project Manager. Castro explains that the practical benefits of collaboration using innovative tools are considerable. “A lot of these types of projects now are run through centralized models, Previously, maybe 20 years ago, everyone had a set of blueprints. Now, however, people are working on different sides of the country, or on different sides of a jobsite. They are collaborating in real time through integration models, through coordination. Everyone’s work is now integrating.”

It is impossible to maintain a successful presence in the construction industry for over six decades without an ability to move with the times. Alongside this, however, is the need to forge and maintain strong working relationships. At COST Inc., building partnerships is a vital component. As Zimmerman explains, not only have these relationships ensured that the company goes from strength to strength, but they also stand as evidence of the true value of having a quality staff. “Our business is built on the relationships that we have throughout the country. Our job is to execute the vision and the wants of the owner. We make sure that we have the best artists and personnel behind the scenes to make those things happen. We execute what our clients want. It’s timeless in a sense, so we do things the right way, we are transparent in how we operate, and the work that we have done on large-scale high-profile projects is world class. This is a product of our personnel.”

These world class projects give an insight into the level of detail and quality that goes into a job for COST Inc. Take the Galapagos Islands at Houston Zoo, for example. With the sharpest eye for detail, COST Inc. worked tirelessly to produce incredible craftsmanship and detail on the project. As Zimmerman shares, the work produced for this job was simply incredible. “That project had a lot of focus on the finer details and on what makes the Galapagos Islands so unique. So, everything that we did there was very accurate in the real world. It all had a sense of realism to it. The rocks had to look like the Galapagos rock formations. We put a lot of emphasis on it having to look like the real thing. Every aspect, down to the algae and barnacles. A highlight for us would be the workmanship. It is exceptional, a world class exhibit.” Alongside this, Kingdoms of Asia at Fresno Zoo and Lost Island Theme Park in Iowa are also brought up in terms of high-quality projects that succeeded, in part, due to the consistently positive relationships the company has with both clients. “All of those projects are long term relationships. The relationship built over a decade or two decades, creates a tremendous amount of trust. I think people can hear each other better when you have that trust. They want a higher level of detail, and they know we can do that. They trust us to do it. In all three of those examples that actually happened. The architects and the designers have a look, tell us where to get information and references. From there, we turn it into models using computers, 3d printing, and clay models and then we turn it into real life.”

With nearly seventy years of experience at the forefront of Theme and Specialty Construction, COST Inc. has established a reputation as one of the foremost producers in the sector. With that in mind, the question must be asked, where do you go from here? While they remain tight-lipped about specific details, the future is certainly bright for the company with several more high-profile jobs beginning in the near future. As Jared Stanwyck shares, the future will always be one of balance and steady innovation. In an ever-changing industry where new demands are being placed on those at the coal face, it would be remiss of COST Inc. to rest on its laurels. “Right now, we’re focused on North America, but future challenges we anticipate relate to things like, what are we doing to stay ahead of the curve on technological developments? These are rapidly evolving in terms of programs, model integrations, 3D scanning, and even augmented reality. The bar has been raised with higher expectations on precision and fabrication. Given the scope and nature of our projects it’s something we face quite often, but it’s also something we have always embraced. We are always learning and pushing the boundaries of what is possible. Creative thinking and problem solving is what got us here today.