Concrete is only as strong as the steel wire mesh it has to reinforce it – so contractors can’t play games when choosing the best manufacturer for this linchpin product. As the conditions of our world evolve, the quality of our wire mesh has become a primary focus on many construction projects. A changing climate has brought stronger winds, more frequent tornadoes, and other environmental concerns to the northern shield of Ontario and Quebec, while new political realities call for tunnels, bridges, and infrastructure that can even hold up to bombing (an overcaution, yes, but better safe than sorry).

Numesh Inc. has, for a long time, been pushing the needle for what contractors can expect from wire mesh. Numesh, Canada’s largest manufacturer in the space, has turned its home in Laval, Quebec, into a powerhouse for producing top-of-the-line products that are custom engineered specifically for its client’s projects.

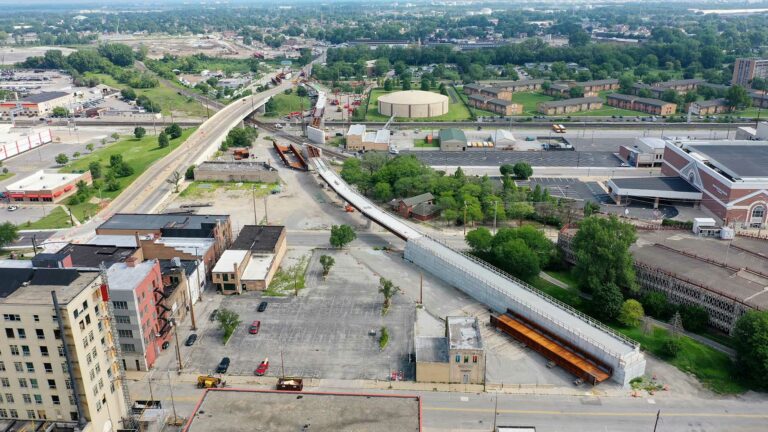

Out of Laval, Numesh’s presence has been felt in projects across Quebec, the Maritimes, Ontario, and the northeastern United States. This reach has only grown with its recent expansion and opening of a new facility in Brantford, Ontario. Just as its products bolster and strengthen the concrete we use to build; this new facility adds to the underlying framework of Numesh’s already industry-leading operation.

Brantford, only a short drive from both Toronto and the US border, offers new logistical advantages for Numesh as it delivers wire mesh to clients on time and within budget, while also tapping into a region that continues to show excellence in the trades and in manufacturing.

Charles Thibault – COO and GM

A stone’s throw away from Hamilton – the city famous for its steel – Brantford and its surrounding area is home to some of the best that Canada’s trades have to offer. Numesh, now operating in Brantford with over 60 employees and counting, has been a welcome addition to the community. “When you walk into the plant,” Charles Thibault, Numesh’s COO and GM, says, “you can see people are excited. We’ve been able to bring in strong trade people with a good mindset on leadership. It’s an awesome team, all working together.”

The response to Numesh’s expansion, both locally and provincially, shows the importance of a new facility like this. The Ontario government welcomed Numesh’s nearly $40 million investment into the new plant and partnered with the company to the tune of $2.9 million as part of the Regional Development Program’s Southwestern Ontario Development Fund. “The opportunity to create new high quality, high paying jobs–that was a big upside for us,” Thibault says.

“The opportunity to create new high quality, high paying jobs–that was a big upside for us.”

As mentioned, the expansion puts the company right where the industry needs it. “For a long time,” Thibault says, “we were looking for another spot to be closer to our customer base. We have a lot of customers in Ontario. The Toronto area alone is one of the biggest construction markets in North America. It’s getting bigger every day, so being close to places like this is important for both serving our current customers and reaching new ones.”

Looking forward, this facility is a launch pad for breaking into the prairies as well as taking on more private market projects in the US. “What makes or breaks this business is the transportation. The closer you are, the more competitive you can be.”

Keeping things cohesive during an interprovincial expansion is no small feat, which is where Numesh’s strong culture and perspective on training has played a large role. Rather than running top-down out of Quebec, Thibault and the leadership of Numesh have built a team in Branford that is an autonomous part of one unified whole. “We don’t just look to develop people,” he says, “we empower them.” Along with the new team in Brantford come eight new state-of-the art machines, six of which are currently in action with two more being commissioned as this goes to press. These facilitate the welding, cutting, and fabrication needed to transform steel wire into welded wire mesh that meet the needs of the specific project at hand. As Thibault shares, every project is different. This means that when contractors look for more than just standard rebar, they turn to Numesh to supply exactly what they need. “There’s around 75 to 100 different general products that we keep in stock at all times,” Thibault says. “We customize these based on the contract and project we’re working on.”

Numesh, in both Laval and Brantford, boasts in-house engineers able to calculate the fabrication of mesh to accommodate any form a pre-caster would need. It’s able to provide an engineering stamp of approval so that the customer does not have to worry whether or not their build will be up to standards, whether it be CSA in Canada or ASTM in the US. Numesh continues to build on this quality. “There’s always new techniques, whether it’s in precast or in construction,” Thibault says. “They’re moving forward in every industry, every customer segment, and it’s keeping us on the edge to develop different services and engineering offerings.”

This commitment to progress has allowed Numesh to touch a wide array of projects since its founding in 1975. This has included everything from an Amazon facility in Ottawa to new battery plants in Ontario coming up soon. As this goes to press, Numesh is even involved with the construction of a major tunnel in Los Angeles, a testament to the company’s growing reach. “We have another site in California that we share with a general contractor. We have a few machines, and we are providing all of our technical expertise in engineering and tradesmanship. It’s exciting to offer them Canadian talent that can support those guys as they fabricate the mesh to use for the tunnel.”

The universal need for steel wire mesh in construction makes for a dynamic work environment at Numesh. According to Thibault, this flexibility has been integral to the company’s success. “It’s allowed us to be very diversified. So sometimes mining can go up, general construction will go down and maybe road construction will be at an all-time high. We can shift our focus based on what’s happening and see steady demand. It’s fun, because we’re always touching different segments and accommodating different customer needs.”

For the COO and GM Thibault, his position at the helm of Numesh is still fresh. In December 2022, he left the concrete construction material giant Lafarge to start the new year in his current role. With 23 years of concrete experience under his belt, Thibault transferred over with strong connections and sensibilities for the market, as concrete and wire mesh are almost always bought hand-in-hand. With that in mind, it is no surprise that his fresh perspective has only strengthened the trajectory of Canada’s largest steel wire mesh manufacturer. “It’s been a very good opportunity to revisit the company mission, vision, and the values with all the employees,” he says. “Now that we have our second location–and almost third soon with California–and a few ideas for acquisition and expansion, it’s been a really good opportunity to sit down with the management team and redefine Numesh 2.0.”

Already at the top of the industry, what can we expect from Numesh 2.0? Beyond the physical growth of the company, sustainability is also a big part of Thibault’s vision. “The more efficient we are in fabricating,” Thibault says, “the less energy we can use, the more environmentally friendly we can be. We’re looking into reducing and reusing our waste by finding opportunities with other industries to adopt a circular economy strategy. For me, becoming greener is the best thing we can achieve.”

From Laval, to Brantford, to California, Numesh Inc., led by Charles Thibault, has a presence as strong as the steel wire mesh that it creates.

For more on Numesh, visit www.numesh.com