The construction world is an ever-changing entity. It finds itself in the unenviable position of being both a driver and responder to change. Any number of considerations may require the industry to undergo a complete overhaul, safety demands, available materials, innovative machinery. Conversely, those within the industry work tirelessly to explore exciting new techniques and procedures which may inspire change in a more positive manner. “A number of drivers have been identified that are expected to prompt changes for the construction sector which could have far-reaching impacts, in relation to skills and training, productivity, innovation, and the overall structure of the industry.” These words came from a British report on construction as a driver for change way back in 2010. What is interesting is that, despite the tumultuous decade that followed the report, the statement is every bit as true today as it was then.

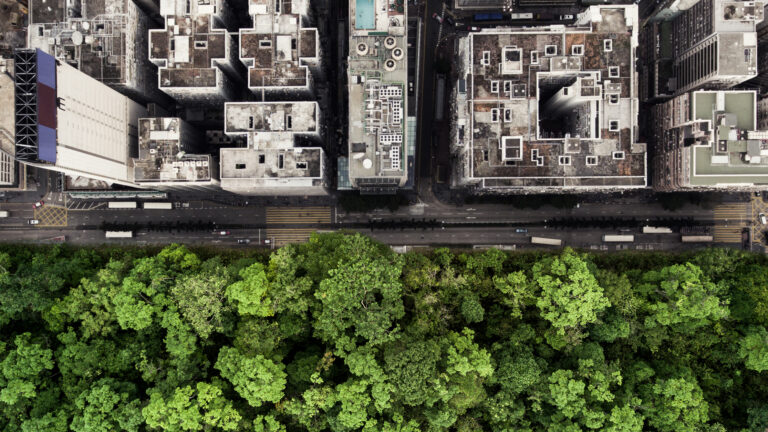

Clearly, there is one global issue that will be the main driver of change within the construction industry going forward, and that is carbon emissions. With governments around the world committing to achieving net-zero emissions, construction is likely to be at the vanguard of whatever changes take place, both in the next few years and in the longer term. Given that construction accounts for around 40% of global emissions —this figure represents both new building work and embodied carbon from existing structures— it is clear that net-zero is going to be the most significant driver for change within the construction industry. This view is echoed by the World Economic Forum. It believes that it is embodied carbon which will prove the most difficult for construction to reckon with. “While construction industry leaders have made great strides on the operational front in recent years, this is but a first step. All too often, embodied carbon has been left out of the equation. With the problem of embodied carbon now taking center stage, this is the moment to make bold commitments and take immediate action.”

So, what does this action look like? Well, when it comes to lowering emissions in new buildings, two considerations become vitally important: what we use and how quickly we use it. Ironic then, given that when we consider the greatest challenges currently facing the industry, we would be hard pushed to find ones greater than shortages in both materials and labor. These two facets of the industry are foundational, and the magnitude of struggle being faced in their absence is considerable. While everything is being done to address these shortages, things do not move quickly. However, the deadline to achieve net-zero is not a fluid one. Change needs to happen fast in this regard. So, imagine the benefit that could be found by working with a product that could allow a $21 million, 96-unit housing complex to be built by just 11 workers without the use of cranes, lifts, saws or metal cutting equipment of any kind.

RENCO is a global force across the engineering, GC, and project development sectors. The company prides itself on providing innovative solutions that are ethically minded. “Since its foundation, RENCO has been providing efficient and economical solutions through the evolution of highly professional know-how and innovative approaches for satisfying client needs.” In recent years, RENCO has brought a product to the market which may be hugely beneficial to the industry on a huge number of levels. RENCO USA has devised intuitively-made building blocks that work like real-life LEGO. The idea, like most excellent ones, is relatively simple. The blocks interconnect seamlessly and are made using a composite of minerals and glass fiber. The injection molding process allows the blocks to be made in any shape needed and they can be used in floors, walls, and roofs.

“Since its foundation, Renco has been providing efficient and economical solutions through the evolution of highly professional know-how and innovative approaches for satisfying client needs.”

According to RENCO co-founder Tom Murphy, Jr. the material is the product of many years research and revision. “We worked on this for more than 10 years. We had to keep changing it to make it better and easier to work with. As we did that, making a building with it got faster and easier, and… the building got stronger each time.” However, despite these challenges, the company came through to produce an incredibly durable material that has everything a contractor would need, and then some. “RENCO MCFR is a state-of-the-art structural building system of interlocking composite building units of various types and sizes of blocks, columns, beams, joists, headers, decking, connectors, etc. These products are all adhesively joined (chemically bonded) to form monolithic structures.”

As the industry struggles to get a handle on its emissions, particularly in the context of dwindling resources and man-power, it can seem alluring —jumping into the next new thing, without giving it proper investigation. Thankfully for the industry, the blocks meet all standards. In fact, according to those at the company, the materials were put through a stringent set of evaluations before being brought onto the market. “The RENCO Structural Building System has been evaluated in ANSI certified laboratories to ASTM standards for structural performance, physical characteristics, and fire resistance. After thorough evaluation, IAPMO-UES approved and issued its Evaluation Report to permit the use of RENCO Structural Building System under the International Building Code.”

The big question now is, do they work? For some, building a house with Lego may seem a little too far-fetched, even for an industry as innovative as construction so having an evidence base will do a lot to convince a skeptical market. With this in mind, and having completed numerous projects internationally, the company has now undertaken its first U.S. project in Palm Beach County, Florida. The $21-million, four-building multifamily project is now nearing completion in Palm Springs, Fla., near West Palm Beach. Construction of the 96-unit development is being managed by Coastal Construction. Incredibly, the units require only 11 staff to install. Furthermore, they are hurricane proof up to Category 5, —a major benefit for housing projects in Florida. RENCO’s system is also earthquake resistant, and the company is now providing the Turkish government with a long-term housing solution to rebuild cities and areas recently affected by catastrophic M7.8 & M7.5 earthquakes and multiple aftershocks. According to company owner, Tom Murphy jr., the system is incredibly easy to use and will have benefits for jobsite managers for many years. “Because workers don’t require any specialized training—the MCFR system uses color-coded plans and 3D models of the interlocking system that new workers can easily follow—the system is an economical choice for the contractor from a labor perspective as well as in terms of tools and materials.

So, where does that leave things? Surely there must be a stumbling block. Medium-rise residential homes built in a few hours with no staff or no tools; it sounds too good to be true. In fact, as we dig deeper into the potential uses and benefits of the product, it seems that it is quite the opposite. “The RENCO Structural Building System currently can include up to five (5) story structures. Through continued research and development, expanded approvals are in process, with full approval to build up to eight (8) stories expected by the end of 2023. As 95% of all Americans live in 8 stories or less, we believe this next level of approval will open an incredible amount of opportunity for use of this revolutionary product.” As plans are now being put in place to achieve the further accreditation needed to ramp up production and education, we are soon going to be faced with the very real possibility of Lego houses. As always, with the construction industry standing out as a driver of change, everything is awesome.