The construction world is a fast-paced, complicated environment with many layers of administration and oversight on its projects. From large construction management companies to general contractors, subcontractors, vendors, various engineering and architectural firms, owners, among others, it can be a complex environment. While this will invariably present challenges to a business, there is one constant truth that has run through the industry for decades. In an industry that is unpredictable and ever-changing by its very nature, the ability to provide reliable, quality services will ensure that construction projects can be completed on schedule and budget. By following the fundamentals and values of good business, ensuring that hard work and honesty are top priority, a business can thrive in the construction industry. At SperryCo, LLC, a geotechnical construction company located in rural upstate New York, meeting the needs of the customer is key and its message is clear. No matter how complicated, complex, or competitive the construction industry is, this is a business that will operate in good faith with an effective, results oriented team.

A female owned and female run business, SperryCo was founded by Erin Sperry in 2018. After a distinguished career as an executive in the heat transfer manufacturing industry, Sperry decided to embark on her lifelong ambition and took the plunge, setting up her own business. Despite SperryCo being a reasonably new member of the industry, the company has experienced significant growth and success. While Sperry leveraged contacts made in her previous career, she admits that the decision to enter the industry was not an easy one. “I have always had the dream of running my own business. I made the difficult decision to leave my previous career as an executive in the heat transfer manufacturing industry and started SperryCo, LLC. I worked with a local general contracting company who had a unique opportunity for a specialty subcontractor to install drilled piles to support a sewer pipeline. This opportunity provided me with a nice project to get me started. My husband Jason Sperry owns a consulting firm specializing in geotechnical engineering, so for me the geotechnical construction business provided the opportunity for us to work together in some ways. I hired experienced specialty equipment operators/superintendents from other drilling companies to manage field operations. Coming from a different industry, I was motivated by the challenge of learning something new. As a seasoned technical leader with experience managing departments such as manufacturing, sales, global supply chain, engineering, and field service, I knew I would be able to successfully transfer my skillset.”

Although women are making some gains at the state and national levels as far as participation in the construction industry from a business administration and direct labor perspective, the outlook remains complex and, particularly in the case of recent “Women in Construction” drives, exaggerated. While there are public programs to help women and other disadvantaged groups pursue work, Sperry believes that the road ahead will be a long one. Unsurprisingly, she is choosing to lead by example. SperryCo has both New York State Women Business Enterprise and New York State Department of Transportation Disadvantaged Business Enterprise certifications. The Disadvantaged Business Enterprise (DBE) program is a federal program run by the United States Department of Transportation (USDOT) through each State’s Unified Certification Program. Small businesses that are independently owned and controlled in both substance and form by socially and economically disadvantaged people are eligible for certification. According to Sperry, these accreditations have certainly helped SperryCo as it navigates a crowded industry.

So, what exactly does SperryCo do? In a sector that may not be known well to those outside the industry, it is a valid question. SperryCo specializes in the construction of geotechnical infrastructure and providing subsurface solutions for heavy/highway and commercial markets. This is achieved through micropiles, drilled and grouted non-displacement piles with reinforcement. Holes between 15 and 150 ft are drilled using either temporary or permanent steel casing and the process is usually used when ground conditions are difficult such as natural or manmade obstructions. In addition to this, SperryCo offers its clients tieback anchors and rock anchors. This is achieved with steel bar assemblies that are installed in pre-drilled holes. Soldier piles, walls, or other constructions are generally fastened by tieback anchors, which are commonly set 15–45 degrees off the horizontal. To provide uplift capability for structures, ground anchors that are bonded in soil or rock and fixed vertically are employed, for instance, if the structure’s bottom is below the water table. What is evident from speaking to Sperry is that this is a field that requires thorough engineering and planning, skilled production teams, and excellent communication and record keeping.

“This is a field that requires thorough engineering and planning, skilled production teams, and excellent communication and record keeping.”

As with every sector of construction, there are challenges. According to Sperry, working outdoors can provide many challenges. However, it is the physical and personal demands that the industry places on workers, with staff required to sacrifice time with their families due to travel commitments and long hours that Sperry identifies as being particularly difficult. “My work is mostly outdoors and requires travel away from home. Having the resilience to withstand working outdoors in the elements, cold, rain and snow, cannot be underestimated and finding employees that not only have the technical skills to operate equipment and organize the project sites, but be away from their families, is a big challenge.” For Sperry, however, these challenges are offset by the excellent staff she has built around her. “I am so fortunate to have a core group of experienced and capable people that have been with the company since 2019, who understand the work, will do any task required, and handle problems systematically.”

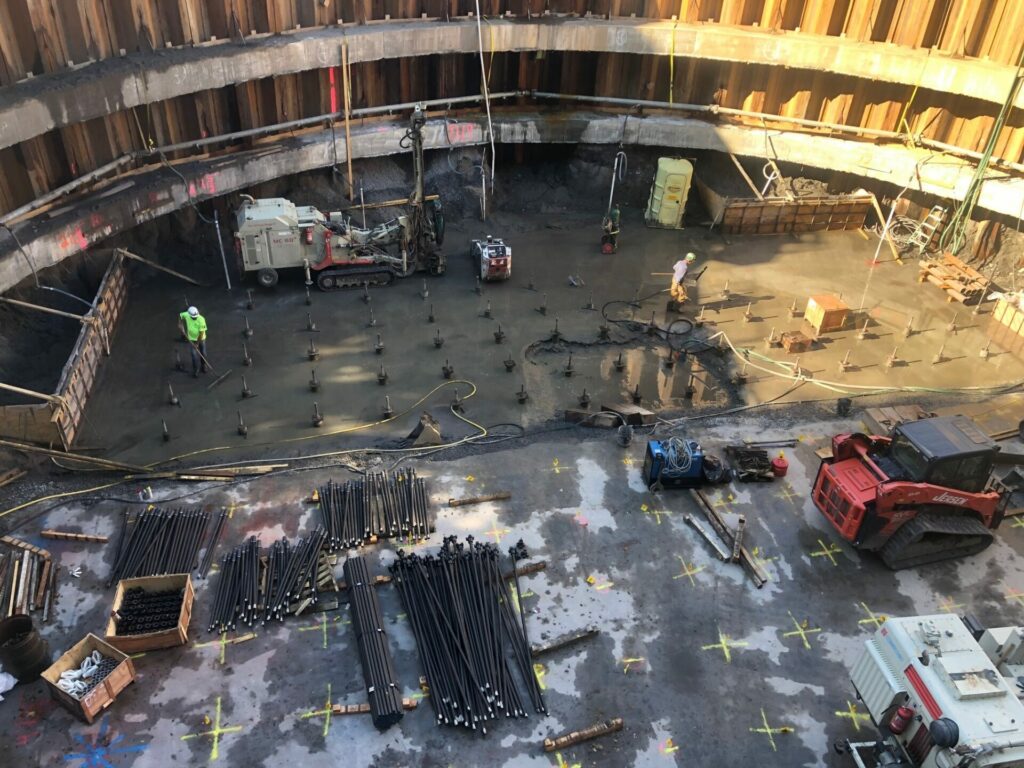

Despite these challenges, SperryCo has undertaken some incredibly exciting projects since its foundation in 2018. One of the most memorable, according to Sperry, was the North Ferry Street project on which SperryCo worked as a subcontractor to the Jersen Construction Group. The North Ferry Street project was a fifteen month long bulk excavation job for a four-story concrete pump station located near the banks of the Mohawk River in the NY city of Schenectady. SperryCo provided design build solutions for a dewatering system and various micropile foundations. Additionally, it provided an active dewatering system for a 110-ft diameter cofferdam. This included 12 deep wells and an active pumping system at 300 gpm. The company had to install 163 micropiles at the bottom of the cofferdam (approximately 35-ft below grade) for the new pump station and 45 micropiles at grade for a generator system.

Wurts Street Bridge

Another project of note was the Wurts Street Bridge rehabilitation project. Originally built in 1921, The Wurts Street Bridge is a historic 1,145-ft long bridge over Rondout Creek, in the City of Kingston, NY. According to Sperry, the scale of this project meant that SperryCo had to use all its in-house skill. “The bridge fell into disrepair and was closed to all traffic in 2020. Our scope of work was part of the anchorage eye-bar rehabilitation. SperryCo worked as a specialty subcontractor to WBC (Wurts Bridge Constructors, LLC), installing six new Permanent Rock Anchors at each of the four corners (vaults) of the suspension bridge for a total of 24 production anchors and 2 additional test anchors. The new Rock Anchors varied from 50 to 90-ft long and were installed at specific angles between 15 and 20 degrees to align with the design of the original bridge anchorage. All the Rock Anchors underwent a series of Performance Tests before being accepted by the NYS DOT.” While these are clearly standout projects for Sperry and her team, she is quick to emphasize that SperryCo takes pride in every job it works on and applies the same level of detail and attention to every single one. As a growing company, SperryCo is in the enviable position of being able to offer a more hands on approach to its clients, something that larger firms may not be able to. As Sperry puts it, the company has a very simple, streamlined operation with minimal overhead, focusing on a few specific nuances of the geotechnical construction field.

While SperryCo may not have been around as long as its competitors, Sperry herself is acutely aware of the importance of maintaining a number of key characteristics. By taking care of its customers, working smart and proactively and maintaining positive relationships, SperryCo is doing just that. With an excellent team and a professional mentality, the company is certainly one to watch. This is best described by Sperry herself, who fittingly describes her company in three simple words; “safe”, “prepared, and “honest. ”

Evidently, the future looks bright for SperryCo.