In December 2019, the Province of Ontario announced that they were phasing in a new regulation under the Environmental Protection Act that, in addition to a number of environmental considerations, would result in reduced construction costs by making it easier to reuse excess soil generated during construction activities. The goal of this regulation was to minimize waste and to provide clear rules on managing and reusing excess soils. By way of context, the Ontario Ministry of the Environment, Conservation and Parks (MECP) estimates that 25 million cubic metres of excess soil is generated in Ontario every year. While most of this excess soil could be reused safely it is often moved off-site because it can’t or won’t be reused at the development site. In response to these concerns, the MECP implemented the On-Site and Excess Soil Management Regulation (O.Reg. 406/19) on January 1, 2021 to help reduce negative impacts and costs from improper management of excess soil such as:

- Noise and dust

- Truck traffic and road damage

- Erosion and drainage

- Other social, economic, health and environmental concerns.

While MECP has created best practice guides and calculation tools to assist with the excess soil regulations, the Greater Toronto Sewer and Watermain Contractors Association (GTSWCA) retained WSP Canada to help its members identify opportunities for the effective and beneficial use of both excavated soils and recycled materials for buried pipe construction. A report published in August 2020, reveals that the production of aggregate in Ontario is approximately 45 to 90 million cubic metres annually. This, coupled with growing demand expected over the next 25 years, is resulting in unsustainable levels of production and impact, alongside the enormous carbon footprint associated with the mining and transportation of new aggregate sources. The Executive Summary of the GTSWCA-WSP identifies the following issues associated with disposing of excess soils:

- Extra costs on many infrastructure projects.

- Environmental impacts related to virgin aggregate extraction in existing agricultural and protected areas.

- Additional trucking distances to import virgin aggregate materials.

- Significantly larger carbon footprint related to the above issues.

The GTSWCA-WSP report also proposes the following key areas of recommendations:

- Performance requirements to ensure suitable performance of serviceability of engineered fill.

- Compaction methods to improve engineering properties of fill.

- Current uses and specifications on backfill material and compaction, and the need to explore reforms for more viable options.

- Guidelines to help assess the suitability of excavated native soils as trench backfill.

- Benefits of using recycled aggregates (or blended with RAP) as trench backfill for all weather placement.

- Recommendations for restructuring public works tenders to allow for greater use of native soils and recycled materials for backfill.

These recommendations, however, are not new. Many years prior to this MECP excess soil regulation, the Ontario Concrete Pipe Association published an article Concrete Pipe Installed with Recycled Aggregate: Good for the Environment and Good for the Economy, in the Fall 2013 edition of the Concrete Pipe Journal. The article recognized and highlighted the opportunities and benefits to using recycled aggregate as a backfill material for concrete pipe, something which neither flexible plastic or corrugated steel pipe products allow. Interestingly, these same opportunities, such as positive environmental impact and more cost effective project, can also be found by using select native soils to install concrete pipe.

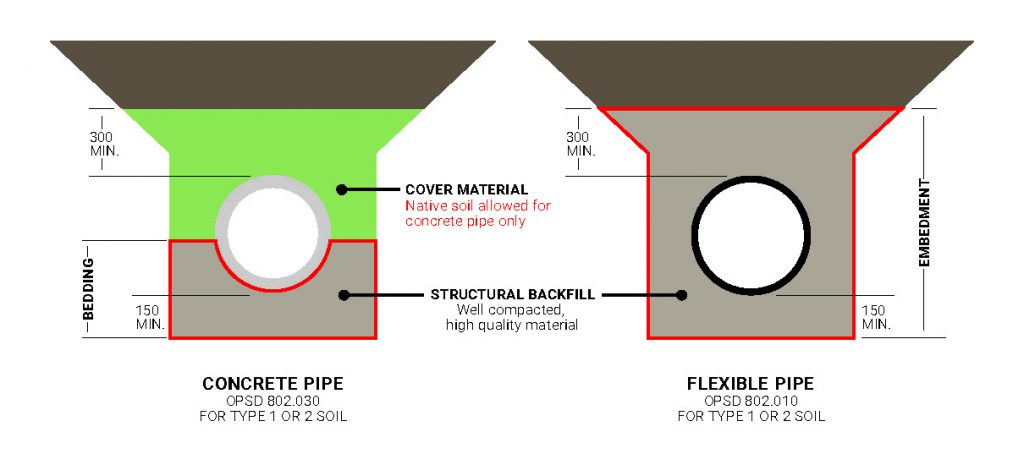

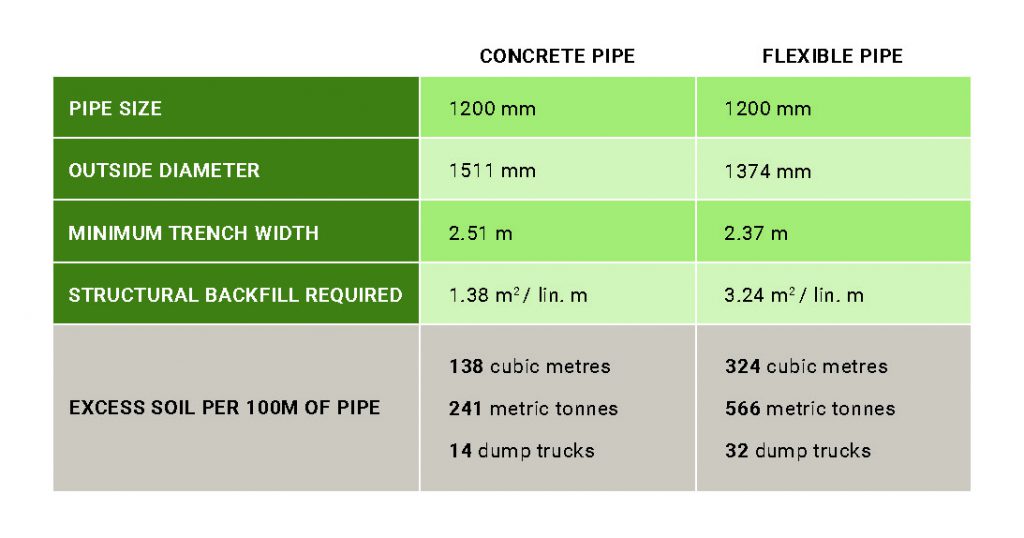

Ontario Provincial Standard Specifications (OPSS.PROV) 401 used by the Ministry of Transportation, Construction Specification for Trenching, Backfilling and Compacting, clearly identifies the differences between the installation requirements of a rigid concrete pipe and flexible plastic or metal pipe for sanitary and storm sewers, pipe culverts, subdrains, forcemains, and watermains. The figure below illustrates the terminology used in Ontario, with the critical backfill soil surrounding each type of pipe highlighted, often referred to as the structural backfill for the pipe.

As highlighted in the figure, the structural backfill is critical for pipe-soil interaction to carry the loads imposed on the pipe and should consist of high quality material and proper compaction effort. For a rigid concrete pipe, this critical zone is limited to the pipe bedding which is from the bottom of the excavated trench to the springline of the pipe due to the inherent strength and load carrying capacity of the pipe. For a flexible plastic or metal pipe, the entire soil envelope from the bottom of the excavated trench to a minimum of 0.3m above the pipe is required to allow the pipe to transfer the loads into its surrounding soil.

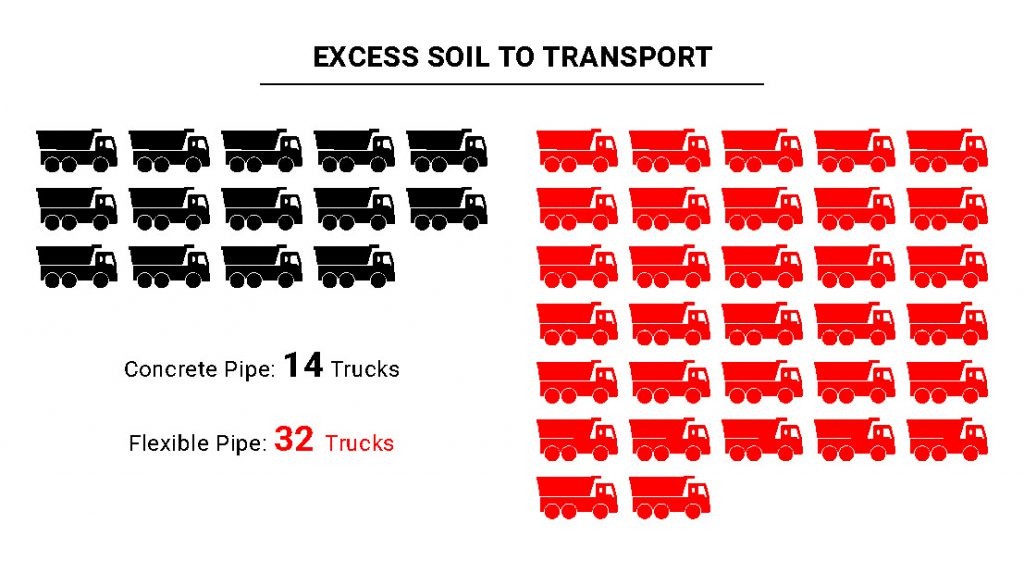

An assessment of these two very different installation details results in a plastic or metal pipe requiring more high quality backfill material while also generating more than twice as much excess soil than a concrete pipe.

In a recent example of how concrete pipe can minimize excess soil generation, and the construction costs related to meeting the new MECP regulation, the City of Ottawa along with local industry National Capital Heavy Construction Association (NCHCA) started their biennial construction specifications review in the summer of 2020. As part of this review process, the City of Ottawa construction specifications were divided up with each component being assigned to working groups. These groups were comprised of both City of Ottawa staff and key industry individuals. The Canadian Concrete Pipe and Precast Association (CCPPA) was asked to join the Water/Sewer Working group.

During the City of Ottawa specification review, the CCPPA proposed a change to the backfill requirement, for reinforced concrete pipe (RCP) only. The proposed change for concrete pipe installation was to allow for select native soils to be used as the cover material above the pipe springline. Under existing regulations, backfill, either Granular A or Granular B, was required to a level of 300mm above the top of the pipe. This requirement related to both concrete and plastic pipe only. It was explained that flexible pipe systems (plastic or metal) require this embedment up to 300mm above the top of the pipe for the flexible pipe system to have the capacity to carry the required loads. However, since concrete pipe does not rely on any structural capacity provided by the cover material above the springline, native soils could be utilised as an alternative material, thereby reducing the amount of excess soil generated.

This change was adopted by the City of Ottawa and is included in the 2021 City of Ottawa Construction Specifications dated March 1st, 2021.

With ever increasing data around the need to reuse excavated soil, it is encouraging that innovative and forward thinking methods are sourced. These regulatory changes will go some way to ensuring that excess soil in concrete piping projects, is retained and recycled onsite. This continuing evolution in specifications, when coupled with locally produced concrete pipe, provides governments and developers with a tremendous opportunity. Not only can the pipe itself be 100 percent recycled at the end of a very long service life, these regulations now encourage both a reduction in the amount of excess soils generated onsite and an increase in the use of properly processed recycled aggregates.