Metal Forms Corporation‘s 115-year journey showcases a legacy of concrete craftsmanship and innovation. Established in 1909, Metal Forms Corporation has meticulously honed its expertise in the fabrication of steel and poly forms, alongside specialized concrete finishing equipment. Originally creating concrete forms for monolithic homes designed by Thomas Edison, the company has transitioned to meet the critical demands of heavy highway paving and commercial flatwork sectors. Today, its portfolio encompasses essential tools and machinery for constructing everything from pedestrian pathways to expansive airport pavements, roadways, dams and spillways, concrete monorail forms, and meticulously engineered bridge parapets and traffic management barriers.

Headquartered in Milwaukee, Wisconsin, Metal Forms boasts a comprehensive operational scope that integrates manufacturing, sales, and engineering. The organization is characterized by its deeply ingrained corporate culture of expertise and loyalty, with many team members boasting tenures spanning several decades. “Our success is thanks to our people,” says Metal Forms President, Dan Block. “You can have all the equipment in the world, but if you don’t have the right people in place to make it run and make it efficient, you’re just spinning your wheels. Our employees are part of our family. They’ve been here for many, many years. They know our product, they know our customers, they know our equipment, they know our processes, and without them, we wouldn’t be where we are today.” This depth of experience is further enriched by the company’s familial leadership, now in its third generation, which preserves a legacy of intergenerational skill and dedication within the workforce.

Distinguishing Metal Forms Corp in a competitive marketplace is its unwavering commitment to the client experience. Leveraging over a century of industry presence, the company has built a formidable reputation for dependability and quality. From the moment of initial contact, customers interact with exceptionally knowledgeable staff, ensuring that every transaction is handled with efficiency and expertise. “We take pride in that. When somebody calls here, they’re dealing with a company they know, products they’ve come to rely on. They come to us because they know we’ll help them solve a problem they have,” says Block. This relentless focus on client satisfaction, combined with its storied history, carefully cultivated relationships, and specialized focus on precise concrete placement solutions, cements Metal Forms Corporation’s status as a respected leader in the industry, consistently chosen by contractors who value reliability and superior service execution.

Metal Forms offers a comprehensive range of products and services tailored to the construction industry, specializing in concrete formwork and associated machinery. Its offerings are split into two primary categories: custom solutions for large-scale projects like airports and highways, and standardized products for more general construction needs such as sidewalks and curbs.

The evolution of its services reflects broader industry trends, notably the increasing integration of technology. Metal Forms has harnessed automation and robotics to enhance production efficiency and quality. These advancements enable quicker turnarounds on custom projects and, most importantly, ensure consistent quality in mass-produced items, crucial for meeting the stringent demands of both large contractors and its distributor networks.

“This year, Metal Form will celebrate its 115th anniversary.”

The diversity of Metal Forms Corporation’s product range and services significantly contributes to its market resilience and growth. By catering to both custom and standard construction needs, they can engage a wide array of clients and projects, from local community improvements to major international airports. This versatility not only broadens its client base but also stabilizes the business against market fluctuations that might affect one sector of the industry more than another.

Its strategy for growth hinges on adaptability and proactive evolution. Metal Forms closely monitors advancements in construction materials and techniques, such as the emerging environmental standards that affect concrete formulation. The shift toward more sustainable practices, like the use of environmentally friendly concrete mixes and battery-powered equipment, exemplifies its commitment to adapting products in line with industry evolutions. This forward-thinking approach ensures they remain competitive and aligned with customer needs and regulatory demands.

Metal Forms is set to expand its roller screed product line, anticipating advances in equipment to accommodate larger and thicker concrete pavement projects. Currently limited by the size of projects they can undertake, the introduction of larger, heavier machinery will allow the company to handle increased slab thicknesses required for more substantial infrastructure works such as major roads and highways. This evolution aligns with the growing demand for robust construction solutions capable of supporting larger-scale developments and ensures that Metal Forms Corporation remains at the forefront of the construction equipment industry.

The company’s willingness to expand into new technologies and markets, demonstrated by its adoption of robotic processes and exploration of battery-powered construction equipment, showcases its initiative to lead rather than follow industry trends. Metal Forms Corporation’s ability to integrate these technologies without displacing its skilled workforce highlights its balanced approach to growth—leveraging new technologies while valuing human expertise.

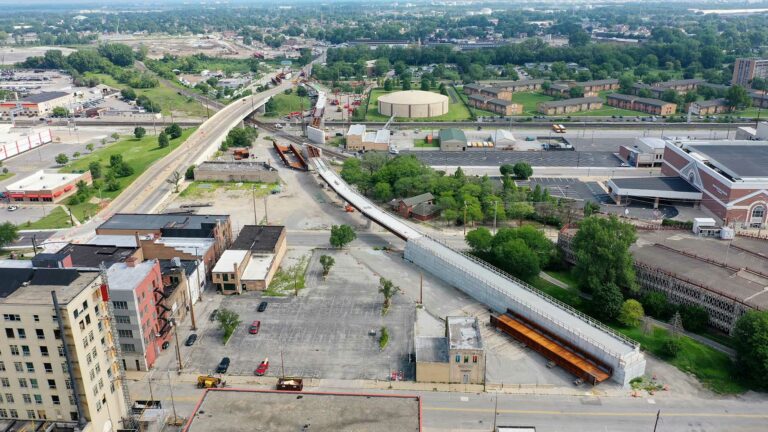

Recently, Metal Forms has made substantial contributions to two major infrastructure projects that have significantly elevated its standing within the concrete construction industry. The first of these projects involved essential contributions to the comprehensive renovation of Los Angeles International Airport (LAX), in preparation for the 2028 Olympics. The company supplied specialized formwork for the construction of tramways and other infrastructure upgrades essential to the airport’s expansion. This included precision-engineered concrete forms for LAX’s new monorail system, as well as extensive formwork for taxiways and security barriers close to terminal areas. This project not only highlighted Metal Forms’ ability to manage complex and large-scale requirements but also anchored its position as a critical player in national infrastructure projects.

The second project of note was the reconstruction of the spillway of the Lewisville Dam, in Texas, where Metal Forms provided advanced formwork solutions critical for the project’s success. The company’s formwork was pivotal in facilitating the precise placement of concrete, integrated with extensive rebar and water stops, to effectively manage water overflow during high-rainfall periods. The formwork designed by Metal Forms proved essential in ensuring the durability and effectiveness of the upgraded spillway, showcasing the company’s expertise in engineering solutions that withstand environmental stressors.

The successful execution of these projects has not only reinforced Metal Forms Corporation’s reputation among top-tier contractors but has also expanded its exposure to a broader range of large-scale construction initiatives. This enhanced visibility has positioned Metal Forms as a preferred partner in the industry, known for its reliability and the high quality of its bespoke formwork solutions. These projects serve as benchmarks in the company’s portfolio, demonstrating its capability to innovate and execute at the highest levels of technical and operational excellence, thereby supporting its continued growth and prominence in the construction sector.

As Metal Forms Corporation continues to make strides in the realm of infrastructure development, its commitment to excellence and innovation remains unwavering. Building on the success of its recent projects, the company is now fully immersed in a transformative endeavor at the Pipestem Dam in North Dakota, a project that exemplifies its dedication to enhancing the resilience of critical infrastructure. This project, led by Barnard, is intended to enhance the dam’s resilience against potential high-hazard events. Recognizing the urgency due to the dam’s proximity to cresting during seasonal snow melts, this project is crucial for reinforcing the dam’s emergency spillway against erosion. The modifications include extensive work on the existing spillway, such as the construction of a labyrinth weir and a roller-compacted concrete (RCC) terminal structure, alongside significant excavation and the enhancement of training dikes.

Metal Forms is contributing significantly by supplying over 3,300 lineal feet of 24-inch-high steel edge forms, critical for the RCC aspects of the project. This involvement not only underscores Metal Forms’ capability in handling large-scale infrastructure projects but also highlights its role in bolstering the safety and durability of essential water management structures.

This year, Metal Form will celebrate its 115th anniversary. This significant milestone is an opportunity to reflect on the company’s journey, tracing back to its inception by the Miller family in the early 1900s. Founded by G. H. Miller, the company emerged from the growing need for concrete formwork during the transition from horse-drawn carts to modern road-building equipment. Tom Miller, current CEO and third-generation leadership, has steered the company through decades of evolution, adapting to changing technologies and market dynamics.

One of the secrets to Metal Forms’ longevity lies in its ability to embrace technology without compromising its core values. Over the years, the company has leveraged advances in digital platforms, social media, and project-tracking software to enhance customer reach and efficiency. “Our evolution is deeply intertwined with technological progress, reshaping how we engage with and serve our customers. When I joined nearly three decades ago, our interactions were primarily in person, involving extensive travel. Technology has revolutionized our approach, saving us countless hours on the road and in airports. We now leverage websites, social media platforms, and advanced project-tracking software to expand our reach and connect with markets that were previously out of reach. This shift has been particularly transformative in recent years, opening up new avenues for growth and enhancing our ability to engage with customers on a more visual and interactive level,” says Block. Despite these developments, Metal Forms remains steadfast in its commitment to its core customers and products. By staying true to its expertise and focusing on solutions that align with its strengths, Metal Forms has built a reputation for reliability and integrity in the industry.

Metal Forms’ impact on the industry is evident in its approach to customer relationships. The company’s emphasis on understanding and addressing customer needs has earned it the trust of contractors nationwide. By maintaining a balance between traditional values and modern practices, Metal Forms continues to be a trusted partner in the construction industry, poised to shape its future for years to come.

The future of Metal Forms Corp appears promising, with a focus on steady, sustainable growth driven by customer relationships and market expansion. With a strong foundation built on over a century of experience and a commitment to evolving with the industry, the company’s focus on staying true to its core values while embracing new technologies and market trends positions it well for continued success.

One key aspect of Metal Forms’ future is likely to be its expansion into new markets and geographical areas. As the company continues to showcase its expertise and reliability in the United States, opportunities may arise to continue to explore international markets, further increasing its reach and impact. Metal Forms’ dedication to innovation and product development is expected to drive future growth. By staying at the forefront of technological advancements in concrete formwork and construction equipment, the company can continue to meet the evolving needs of its customers and maintain its competitive edge in the industry.